Clés USB en bois personnalisées en Chine utilisent généralement du bois naturel, intégrant de manière transparente la technologie moderne à l'esthétique naturelle. La Chine dispose d'une chaîne industrielle complète et de techniques de traitement éprouvées, ce qui permet aux fabricants d'offrir des services complets allant de la sélection des matériaux à la production en série, en passant par la conception et le prototypage. Qu'il s'agisse de graver au laser de simples logos ou d'imprimer en couleur des motifs complexes, les fournisseurs chinois sont en mesure de répondre rapidement et de reproduire fidèlement les dessins.

Plus important encore, les quantités minimales de commande raisonnables et les prix compétitifs permettent aux petites et moyennes entreprises (PME) de personnaliser facilement leurs produits. Dans les sections suivantes, nous examinerons les avantages de la personnalisation chinoise. clés USB en bois et découvrez comment sélectionner les fournisseurs appropriés pour ajouter un charme unique à votre marque.

Quels sont les matériaux proposés par les fabricants chinois de clés USB en bois ?

Les matériaux couramment utilisés pour les clés USB en bois sont le bois naturel, le composite de bambou, le noyer, le hêtre, l'érable, le cerisier, etc. Chaque type présente des caractéristiques distinctes en termes de couleur, de veinure, de texture, de respect de l'environnement, de durabilité et d'attrait esthétique.

| Nom du matériau | Images matérielles | Couleur | Motif du grain | Pour |

| Bois de caoutchouc |  | Marron clair à moyen | Droit, subtil | Abordable, écologique, facile à travailler |

| Journal |  | Naturel (varie selon les espèces) | Brut, inégal | Aspect rustique unique, respectueux de l'environnement |

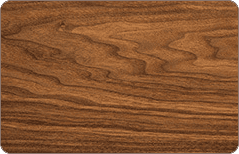

| Noyer |  | Marron chocolat noir | Tourbillons, ondulations | Aspect luxueux, durable, haute résistance aux chocs |

| Pin |  | Jaune pâle-blanc | Grain droit et ouvert | Léger, abordable, facile à peindre et à teinter |

| Érable |  | Doré clair à rougeâtre | Fine, uniforme | Dur, durable, résistant à l'usure, finition lisse |

| Bambou |  | Jaune clair avec des reflets verts | Rayures verticales denses | LigEco-friendly, léger, naturellement antimicrobien |

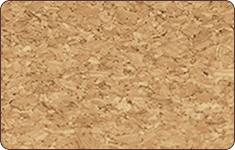

| Liège |  | Fauve clair avec des taches brunes | Cellulaire, poreux | Léger, absorbant les chocs, hypoallergénique |

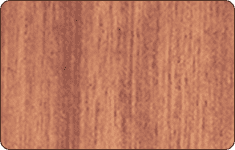

| Bois de cerisier |  | Rose-rouge avec l'âge | Fins, bouclés | Ton rougeâtre élégant, texture lisse, dureté modérée |

| Bois de rose |  | Brun rougeâtre profond | Dense, irrégulier | Grain foncé luxueux, très durable, excellente aptitude au polissage |

| Hêtre |  | Crème pâle à brun clair | Droit, subtil | Solide, indéformable, abordable |

Quelles sont les clés USB en bois les plus populaires ?

Les clés USB en bois les plus recherchées allient fonctionnalité et esthétique naturelle, pour répondre aux différentes identités de marque et aux préférences des consommateurs. Voici les principales tendances :

Clé USB en bois de noyer:Le noyer, d'une élégance intemporelle, associe de riches tons brun-chocolat à des veinures tourbillonnantes ou ondulées distinctives pour une esthétique luxueuse et organique. En tant que bois dur et dense, le noyer offre une durabilité exceptionnelle, une résistance aux chocs et une chaleur naturelle, ce qui le rend idéal pour les cadeaux d'entreprise haut de gamme, les accessoires technologiques de qualité supérieure ou les créations sur mesure.

Sa patine subtile s'accentue avec le temps et lui confère du caractère, tandis que son approvisionnement écologique (souvent certifié FSC) séduit les acheteurs soucieux du développement durable. Légers mais robustes, les disques en noyer se marient parfaitement avec des accents métalliques ou des finitions minimalistes, offrant à la fois un luxe tactile et une fonctionnalité fiable - parfaits pour les marques cherchant à élever leurs articles-cadeaux ou leur image de marque avec sophistication et style durable.

Clé USB en bois de bambou:Le ton jaune pâle discret et le grain droit du bambou confèrent au lecteur une apparence simple et élégante. Le matériau composite en bambou confère à l'ensemble du kit USB une ambiance naturelle, offrant un toucher à la fois léger et chaleureux. Issu de l'agriculture durable, le bambou pousse rapidement et est hautement renouvelable. Malgré sa légèreté, il présente une grande résistance à la traction et ne risque pas de se fissurer ou de se déformer. Le grain distinct et raffiné du bambou crée une esthétique rafraîchissante et apaisante, alliant durabilité et charme organique.

Processus de personnalisation des clés USB en bois

(1) Sélection du matériau bois

Série de bois dur:Ebène (densité : 1,27g/cm³) : Idéal pour les clés USB cryptées haut de gamme. Ebène (haute résistance à la corrosion) : Convient aux scénarios professionnels.

Série Softwood:Bois naturel : Polyvalent pour les conceptions générales. Composite de bambou : Facile à sculpter, parfait pour les logos personnalisés,Oak : Flexible, adapté aux structures complexes,Maple : Grande élasticité, idéal pour les designs complexes.

Approvisionnement en noyaux USB:

Utiliser des noyaux USB métalliques entièrement encapsulés (résistants aux chocs et à l'oxydation).

Capacité recommandée : 2-256 Go (optimisation des coûts de personnalisation).

Testez la compatibilité de base : Assurez-vous que les ports USB ne sont pas obstrués et qu'ils sont compatibles avec les systèmes d'exploitation courants.

(2) Finalisation de la conception du boîtier USB

Calcul des dimensions :

Épaisseur standard : 7-9 mm ; réserve de 2 mm de retrait (en raison de la déformation due au séchage du bois).

Protection du port USB : Réservez un espace tampon de 3 mm autour de l'interface pour éviter les dommages dus aux collisions.

Conception structurelle :

Type divisé : Corps principal + couvercle (magnétique/clapable), convient pour les sculptures complexes.

Type intégré : Bois massif creusé (nécessite un meulage électrique), idéal pour les styles minimalistes.

Compléments fonctionnels : Intégration de fentes pour puces NFC, de trous pour lanières, etc.

(3) Traitement du boîtier de la clé USB

Découpe : Utiliser des scies électriques ou des machines CNC pour une découpe précise (erreur d'épaisseur ≤ ±0,1mm).

Gravure des fentes : meulage électrique → sculpter les coins intérieurs (R ≥ 1mm) → poncer avec le grain 240#. Étape clé : Appliquer de l'huile de cire à bois à l'intérieur des fentes pour protéger l'âme.

Usinage de précision :

Gravure CNC : Logos (profondeur : 0,2 mm) pour éviter les faiblesses structurelles.

Gravure laser : motifs décoratifs (puissance : 30W, vitesse : 100mm/s).

(4) Assemblage et essais

Processus de base :

- Intégration du noyau : sécuriser les puces USB avec de la colle thermofusible ; couvrir les ports avec du ruban adhésif en polyimide.

- Assemblage des coques : Coller les coques supérieures/inférieures à l'aide d'une colle à bois, renforcée par des mécanismes magnétiques/clap-fit. Presser et durcir pendant 24 heures.

- Améliorations : Incorporer des trous pour cordons magnétiques ou des fentes NFC lors de l'assemblage.

Essais :

- Insertion/Extraction : 500 cycles pour vérifier la stabilité du port.

- Test de chute : chute libre de 1,5 m (la protection des angles doit être conforme aux normes).

- Test de fonctionnalité : vérifier les performances de stockage et de lecture/écriture des données.

(5) Emballage

- Intégration du noyau : sécuriser les puces USB avec de la colle thermofusible ; couvrir les ports avec du ruban adhésif en polyimide.

- Assemblage des coques : Coller les coques supérieures/inférieures à l'aide d'une colle à bois, renforcée par des mécanismes magnétiques/clap-fit. Presser et durcir pendant 24 heures.

- Améliorations : Incorporer des trous pour cordons magnétiques ou des fentes NFC lors de l'assemblage.

Quel est le MOQ pour les clés USB en bois ?

La plupart des fabricants chinois de clés USB en bois exigent généralement une quantité minimale de commande (MOQ) d'environ 100 unités pour les produits personnalisés. Cet équilibre garantit une production efficace et un contrôle des coûts tout en vous permettant de tester des échantillons avant de passer des commandes en masse. Si vous avez besoin d'une quantité de commande inférieure ou de modèles comportant des matériaux mixtes ou des combinaisons de couleurs, vous pouvez négocier avec les fournisseurs, car nombre d'entre eux proposent des solutions flexibles adaptées aux besoins des petites et moyennes séries.

Scénarios clés en matière de qualité de fabrication :

- Personnalisation des produits prêts à être expédiés : La plupart des fournisseurs commencent à 100 unités. Certains produits prêts à être expédiés peuvent être commandés à partir d'une unité.

- Modèles nécessitant l'ouverture d'un moule : Les moules personnalisés (par exemple, les lecteurs en bambou/bois en forme de U) nécessitent généralement une QMOS de 500 unités.

- Commandes d'échantillons : de petits lots (par exemple, de 3 à 50 unités) peuvent être disponibles mais entraînent souvent des frais d'échantillonnage supplémentaires.

Pour les exigences particulières (par exemple, les matériaux hybrides ou les finitions uniques), il convient de toujours confirmer la flexibilité du MOQ directement auprès des fournisseurs.

Pourquoi les clés USB en bois du même lot présentent-elles des variations de couleur et des textures différentes ?

Même au sein d'un même arbre, le bois provenant de différentes parties présente des variations naturelles de couleur dues aux conditions environnementales de croissance et aux différences d'absorption des minéraux (par exemple, le bois de noyer peut naturellement passer d'un beige clair à un brun profond). L'orientation de la coupe a également un impact sur l'uniformité de la texture : le tronçonnage (perpendiculaire au fil) et le sciage en long (parallèle au fil) produisent des motifs nettement différents. Si les orientations de coupe ne sont pas strictement normalisées au cours de la production de masse, des incohérences de texture apparaissent au sein d'un même lot.

Les fluctuations de la finition de la surface contribuent également aux disparités. Les échantillons poncés et huilés à la main peuvent différer des lots produits en masse à l'aide de revêtements pulvérisés, ce qui entraîne une épaisseur de couche inégale (par exemple, les finitions mates et brillantes altèrent la visibilité des veines du bois). Un mauvais contrôle de la teneur en humidité (idéalement 8-12%) peut également entraîner un rétrécissement et un gauchissement après le traitement, exposant ainsi de nouvelles textures.

Solutions :

- Fournir des nuanciers physiques (par exemple, Pantone Wood tones) et les spécifier dans les contrats : "Variations de texture naturelle autorisées, mais écart de couleur de base ≤10%".

- Documenter les étapes de la production : Prendre des photos/vidéos pendant la coupe du bois, le ponçage et l'huilage afin de garantir la cohérence de l'ensemble.

- Utilisez des colorimètres pour quantifier les différences de couleur (ΔE ≤3 est acceptable).

- Pré-tri et assemblage : classer les coques en bois transformées par couleur (par exemple, qualité A foncée, qualité B claire) et regrouper les produits de même niveau dans le même emballage.

Certifications pour les clés USB en bois

| Région | Certifications requises |

|---|---|

| L'UE | CE + RoHS + REACH + FSC |

| ÉTATS-UNIS | FCC + FSC |

| Japon | PSE + FSC |

| Mondial | ISO 9001 + USB-IF |

Quel est le délai de production des clés USB en bois ?

Voici une analyse détaillée des délais de production des clés USB en bois, y compris les processus standard, les facteurs d'influence et les stratégies permettant d'accélérer les commandes :

Calendrier de production standard (pas de circonstances particulières)

| Phase de production | Durée Fourchette | Actions clés |

|---|---|---|

| Confirmation de l'échantillon | 3-12 jours | Création d'un échantillon (y compris 3 révisions) + frais de port aller-retour |

| Préparation de la production | 5-7 jours | Approvisionnement en matériaux (bois/électronique) + débogage des moules |

| Production de masse | 7-15 jours | Séchage du bois (3-5 jours) + gravure/impression laser + assemblage + contrôles de qualité |

| Emballage et expédition | 2-5 jours | Emballage sur mesure (traitement contre l'humidité) + logistique et dédouanement |

| Total | 5-30 jours | Commandes standard (MOQ ≥500 unités) |

Avantages concurrentiels des fabricants chinois

| Métrique | Usines chinoises | Usines dans l'UE et en Asie du Sud-Est |

|---|---|---|

| Prix unitaire | $3.5-6.0 (varie selon le matériau) | $8.0-12.0 |

| Quantité minimale de commande | 100-500 unités | 1 000+ unités |

| Délai d'exécution | 15-30 jours | 45-60 jours |

| Capacité de personnalisation | Soutien à l'ensemble du processus (des matériaux à l'emballage) | Limité aux moules standard |

Combiner une production agile avec un savoir-faire traditionnel et une technologie de pointe pour fournir des produits personnalisés de haute qualité à des rapports coût-performance exceptionnels. Donner la priorité aux usines certifiées ROHS,FCC,BSCI,ISO9001,FSC, dotées de capacités de gravure au laser et d'une expérience éprouvée en matière d'exportation afin de réduire les coûts tout en garantissant la qualité.