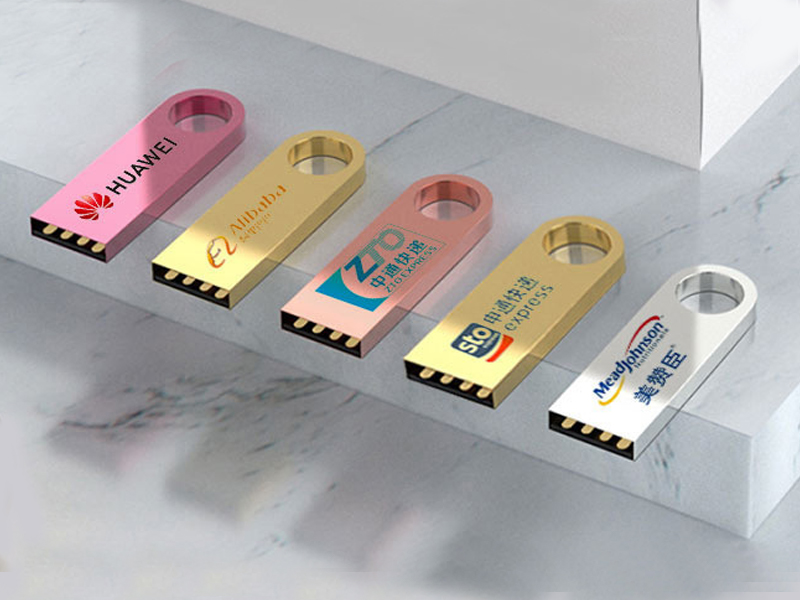

Have you seen other companies with interesting customised USB flash drives in their company logo shape and thought to yourself that it’d be great to have your own company logo in the shape of a USB drive? Well, the answer is yes, you absolutely can! Along with being a useful office gift, a personalised USB flash drive is a travelling billboard for your brand. The entire process of personalisation involves four short and simple steps: design, mould, sample, and production. We’ve put together a simplified explanation below so that it’s easy to understand the process of personalisation.

Step 1: How to Determine the Mold Creation Method for Custom USB Drives?

The first step in the customisation progress is to send your company logo design to a professional USB flash drive supplier. Depending on the complexity and shape of a logo, the manufacturer will then choose the appropriate customisation technique. More than 90% of corporate logos use a 2D flat design – this can be injected moulded onto the USB flash drive to achieve near perfect accuracy in reproducing the logo details. This is a mature and low cost process. For logos with complex structures and needing a three-dimensional effect, manufacturers will move towards 3D mould formation, where multiple processes areused to create a raised textured effect. In either method, a professional manufacturer will blend seamlessly your logo into USB design.

| D Solution | Suitable Logo Types | Technical Parameters |

|---|---|---|

| 2D Flat Engraving | Text, simple graphics, flat icons | Precision: ±0.1mm |

| 3D Injection Molding | Complex 3D logos, animal shapes, etc. | Supports multi-surface engra |

Step 2: What Are the Requirements for the Images Provided by the Client? What Exactly Needs to Be Drawn?

Clients must submit logo images that meet the following specification:

Vector files (AI, CDR format) are the best choice, as they can be infinitely scaled for accurate mold creation. If raster images (JPG, PNG format) are supplied must have no less than 300dpi resolution, and be at least 500×500 pixels in size.

Using these materials, the manufacturer’s designers will develop mold blueprints, including the front, back and sides of the USB drive, and dimensions. For example, standard USB drives are typically 3–8 cm in length, 1.5–3 cm wide and 0.5–1 cm thick. Designers may adjust these dimensions suitably for the logo & overall USB to be correct for mold making.

Blueprint Contents:

- 3D orthographic views (front + side + top)

- Precise dimension annotations (length/width/height ±0.05mm tolerance)

- Logo depth markings (e.g., embossed depth: 1.2mm)

- Delivery format: PDF + 3D model files (STEP/IGS formats for preview)

Step 3: How Are Mold Samples Made? How Long Does It Take?

Once the blueprint for the mold is finalized, the sampling stage begins. For the vast majority of custom USB designs, the chosen mold material is PVC (polyvinyl chloride); a low cost and highly plastic substance that is strong and durable. The design process takes 3 working days, during which time the factory will take an injection moulding machine and heat and melt the PVC, inject that into the custom mould and then cool it down to create a sample. Once finished, the manufacturer will send through real photos and physical measurements for you to check that the end product will look as expected and that the dimensions and logo are also accurate.

Step 4: How Does Mass Production Proceed After Sample Approval?

Once the client has approved the sample, the factory will then begin to mass produce the product. An assembly line workflow follows, which includes material injection, logo printing (via screen printing, heat transfer etc), assembly and quality inspection. For example, during quality inspection the USB drives may be tested for:

- Read/write speed (≥35MBps for USB 2.0, ≥480Mbps for USB 3.0);

- Storage capacity (32GB, 64GB, etc.);

- Cosmetic defects (defect rate kept below 0.5%)

The production cycle typically takes 7–15 working days, depending on order quantity. Once completed, the custom USB drives are packaged and shipped, ready to showcase your brand.

Customizing USB flash drives according to your logo enhances your firm’s image. Below is the general manufacturing process for USB flash drive, from selecting a mold method to uploading your images while still ensuring quality control through an accurate sample.

You will also get all techniques and technical parameters accompanying.

With the help of a qualified manufacturer, you may create great and widespread useful custom USB usb flash drives. Used as a business card to boost your brand presence for corporate gifting, excellent events or employee bonuses.